The oil and gas industry is a cornerstone of the global economy, supplying energy that fuels transportation, manufacturing, and electricity generation. However, transporting these vital resources efficiently and safely poses significant challenges. Oil and gas pipeline maintenance is a critical component in achieving these goals, ensuring that pipelines operate smoothly while minimizing environmental risks and operational disruptions.

The Importance of Oil and Gas Pipeline Maintenance

Maintaining oil and gas pipelines is essential for several reasons. Firstly, pipelines are subject to wear and tear from the materials they transport, environmental conditions, and external factors such as land subsidence or nearby construction. Without regular maintenance, these factors can lead to leaks, ruptures, and other failures that can have devastating environmental impacts and pose safety risks to workers and communities.

Secondly, effective oil and gas pipeline maintenance enhances operational efficiency. Regular inspections and maintenance activities help identify potential issues before they escalate, reducing downtime and repair costs. Additionally, a well-maintained pipeline system can improve the overall reliability of supply, ensuring that oil and gas reach their destinations without interruption.

Finally, regulatory compliance is another driving force behind the need for diligent oil and gas pipeline maintenance. Governments and regulatory bodies around the world enforce strict guidelines regarding pipeline safety and environmental protection. Companies that fail to adhere to these regulations not only risk hefty fines but also damage their reputations and public trust.

Key Components of Oil and Gas Pipeline Maintenance

1. Regular Inspections

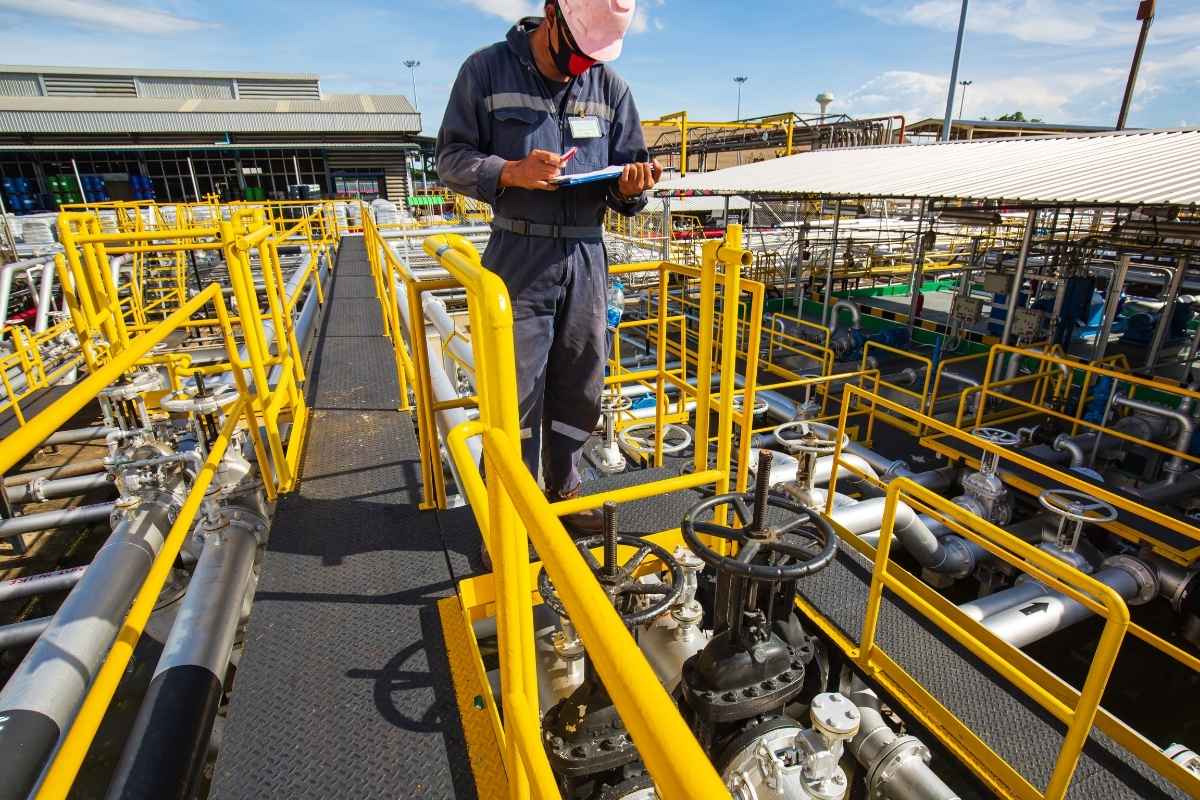

Inspections are the backbone of any effective oil and gas pipeline maintenance program. Using advanced technologies such as smart pigs (pipeline inspection gauges) and drones, operators can assess the condition of pipelines without disrupting operations. These inspections help detect corrosion, cracks, and other anomalies that may compromise the integrity of the pipeline.

2. Corrosion Management

Corrosion is a significant threat to the longevity of pipelines, especially those transporting corrosive materials. Implementing corrosion management strategies, such as applying protective coatings and using corrosion inhibitors, is essential for preventing damage. Additionally, regular monitoring of corrosion rates helps pipeline operators make informed decisions about maintenance schedules and interventions.

3. Leak Detection Systems

Prompt leak detection is crucial in minimizing the environmental impact of pipeline failures. Modern technologies such as fiber-optic sensing and acoustic monitoring enable operators to detect leaks in real-time. These systems not only help prevent environmental disasters but also enhance operational efficiency by allowing for quick response and repair.

4. Emergency Response Planning

Despite the best maintenance practices, emergencies can still occur. Having a robust emergency response plan is vital for minimizing the impact of a pipeline failure. This plan should outline procedures for leak detection, containment, and cleanup, as well as communication protocols with local authorities and communities.

5. Training and Awareness

Personnel training is a critical aspect of oil and gas pipeline maintenance. Ensuring that employees understand the importance of maintenance practices, emergency protocols, and safety measures is essential for fostering a culture of safety within the organization. Regular training sessions and drills help prepare employees for potential emergencies, improving overall response times.

The Role of Technology in Oil and Gas Pipeline Maintenance

Advancements in technology have revolutionized oil and gas pipeline maintenance. The integration of the Internet of Things (IoT), artificial intelligence (AI), and machine learning has enabled operators to predict maintenance needs and optimize inspection schedules. For instance, AI algorithms can analyze historical data to identify patterns that indicate when and where failures are likely to occur.

Moreover, digital twins—virtual replicas of physical pipelines—allow operators to simulate various scenarios and assess the impact of different maintenance strategies. This proactive approach enables companies to make data-driven decisions, reducing risks and enhancing overall efficiency.

Regulatory Landscape and Compliance

Oil and gas pipeline maintenance is heavily regulated across the globe. In the United States, for instance, the Pipeline and Hazardous Materials Safety Administration (PHMSA) sets stringent safety standards for pipeline operators. Compliance with these regulations is not only a legal obligation but also a critical aspect of corporate responsibility.

Internationally, various organizations, such as the International Pipeline and Offshore Contractors Association (IPLOCA), provide guidelines and best practices for pipeline maintenance. Adhering to these standards helps companies maintain their licenses to operate and build trust with stakeholders.

Challenges in Oil and Gas Pipeline Maintenance

Despite the importance of oil and gas pipeline maintenance, several challenges persist. One significant issue is the aging infrastructure in many regions. As pipelines age, they become more susceptible to failures, necessitating increased maintenance efforts and investments.

Additionally, environmental concerns have prompted stricter regulations, which can complicate maintenance efforts. Companies must balance compliance with operational efficiency, often requiring innovative solutions and technologies.

Finally, the rising cost of materials and labor poses a financial challenge for many operators. Implementing cost-effective maintenance strategies while ensuring safety and compliance is a delicate balancing act that requires careful planning and execution.

Conclusion

In conclusion, oil and gas pipeline maintenance is a crucial element in ensuring the safe and efficient transportation of vital energy resources. By prioritizing regular inspections, corrosion management, leak detection, and emergency response planning, companies can mitigate risks and enhance operational reliability.

Embracing technology and adhering to regulatory standards will further strengthen pipeline maintenance programs, paving the way for a more sustainable and responsible energy future. As the global demand for oil and gas continues to grow, the industry must remain vigilant in its commitment to effective pipeline maintenance, ensuring that safety and efficiency remain at the forefront of operations.

Found this article useful? Check out more of our posts at Oil Gas Energy Magazine!