In recent years, the energy sector has witnessed a remarkable transformation driven by advancements in deep offshore technology. This innovative field encompasses a range of practices and equipment designed to exploit oil and gas reserves located deep beneath the ocean’s surface. As the energy demand continues to grow, the significance of deep offshore technology becomes increasingly paramount in meeting global energy needs while ensuring environmental sustainability.

Understanding Deep Offshore Technology

Deep offshore technology refers to the specialized methods, tools, and systems utilized in the exploration, drilling, and production of hydrocarbons from underwater reserves. These reserves are often located in challenging environments, typically at depths exceeding 1,500 meters (approximately 4,921 feet). The complexities associated with these depths necessitate cutting-edge technology and engineering solutions.

The Evolution of Deep Offshore Technology

The roots of deep offshore technology can be traced back to the early 20th century, with the first successful offshore drilling operations beginning in the 1940s. However, it wasn’t until the 1970s that significant advancements began to emerge. The introduction of semi-submersible rigs, floating production systems, and remotely operated vehicles (ROVs) marked a turning point in the industry, enabling operators to access previously unreachable reserves.

As technology has evolved, so too have the techniques used in deep offshore drilling. Today, operators utilize dynamic positioning systems, advanced seismic imaging, and enhanced drilling methodologies to improve efficiency and safety. The integration of automation and artificial intelligence into this technology has further revolutionized the sector, allowing for real-time data analysis and decision-making.

Key Components of Deep Offshore Technology

1. Drilling Rigs and Platforms

One of the most critical elements of deep offshore technology is the drilling rig. Various types of rigs are employed based on water depth and environmental conditions:

- Floating Production Systems (FPS): These structures float on the surface of the water and are anchored to the seabed. FPS units are commonly used in deeper waters where traditional fixed platforms are not feasible.

- Semi-Submersible Rigs: These rigs are designed to float on the surface while remaining stable in rough seas. Their unique design allows them to withstand extreme conditions, making them ideal for deep offshore drilling.

- Tension-Leg Platforms (TLP): TLPs are anchored to the seabed using vertical tendons. They offer stability and are often used in ultra-deep water applications.

2. Subsea Systems

Subsea systems play a vital role in deep offshore technology by facilitating the extraction and transport of hydrocarbons from the seabed to surface facilities. Key components include:

- Subsea Trees: These are complex systems of valves and sensors placed on the seabed to control the flow of oil and gas. They are essential for managing production and ensuring safety.

- Flowlines and Risers: Flowlines transport hydrocarbons from the subsea trees to the surface, while risers connect the subsea system to the floating platform.

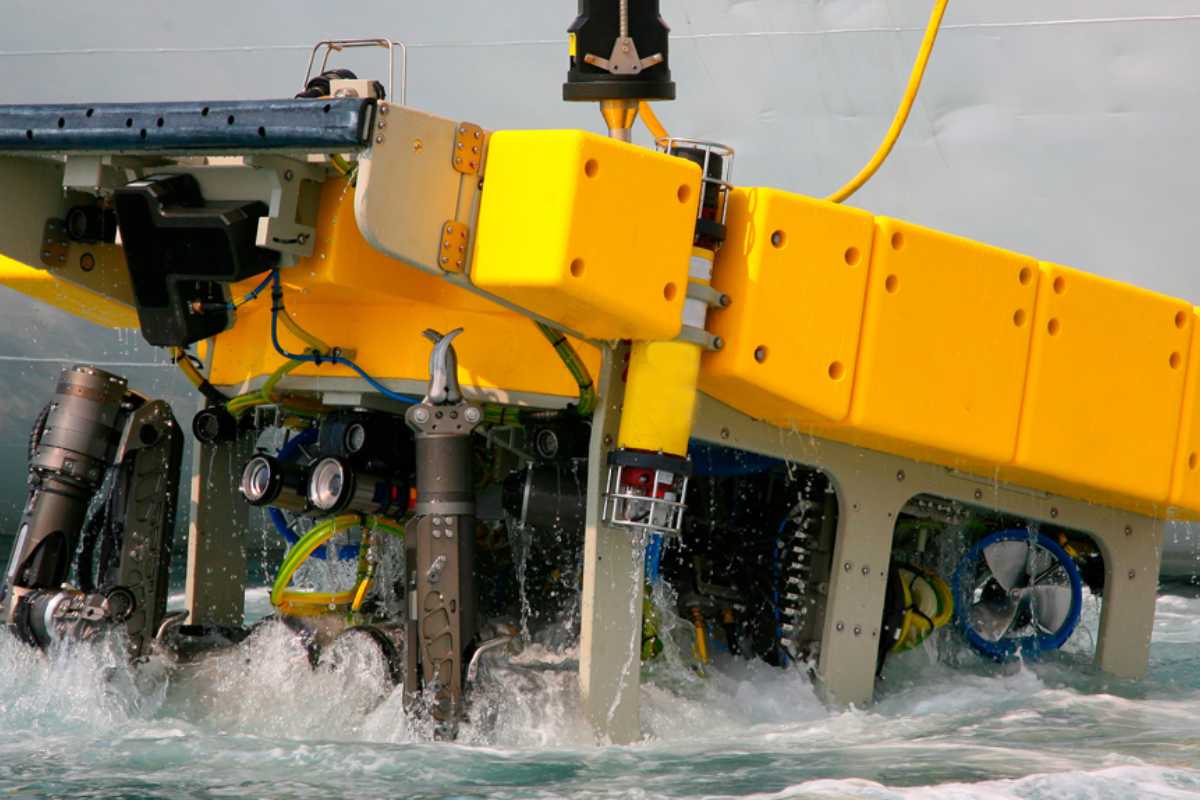

3. Remotely Operated Vehicles (ROVs)

ROVs are crucial in deep offshore technology for conducting inspections, maintenance, and repairs in extreme underwater environments. Equipped with high-definition cameras and robotic arms, ROVs enable operators to perform tasks that would be challenging or impossible for human divers.

Environmental Considerations

While deep offshore technology offers significant benefits in terms of energy production, it also raises environmental concerns. The risks associated with oil spills, habitat disruption, and greenhouse gas emissions must be carefully managed.

To address these challenges, the industry is increasingly adopting sustainable practices, including:

- Advanced Leak Detection Systems: These systems use sensors and real-time monitoring to quickly identify and mitigate leaks, minimizing environmental impact.

- Decommissioning Strategies: As reserves are exhausted, effective decommissioning strategies are essential to ensure the safe removal of offshore structures and restoration of marine environments.

The Future of Deep Offshore Technology

The future of this technology looks promising, driven by continuous advancements and the growing energy demand. The industry is exploring innovative solutions to enhance efficiency and reduce environmental impact, including:

- Digital Twin Technology: This involves creating virtual models of offshore assets to monitor performance and optimize operations in real time.

- Renewable Energy Integration: The integration of renewable energy sources, such as offshore wind, is becoming increasingly important in the energy mix. Hybrid systems that combine traditional hydrocarbon extraction with renewable energy are being developed to reduce reliance on fossil fuels.

Challenges Ahead

Despite its potential, the deep offshore technology sector faces several challenges. These include fluctuating oil prices, regulatory pressures, and the need for significant capital investment. Companies must navigate these challenges while remaining competitive and responsive to market dynamics.

Conclusion

Deep offshore technology stands at the forefront of the energy sector, playing a vital role in meeting the world’s growing energy needs. As the industry continues to evolve, the integration of innovative technologies and sustainable practices will be essential in ensuring the responsible development of offshore resources. By embracing these advancements, the sector can not only enhance production efficiency but also minimize its environmental footprint, paving the way for a sustainable energy future.

In summary, the importance of deep offshore technology cannot be overstated. As we move toward a more energy-conscious world, the advancements in this field will be crucial in shaping the future of energy exploration and production.

Found this article useful? Check out more of our posts at Oil Gas Energy Magazine!